UNRIVALED COATING SOLUTIONS

Driven to provide innovative solutions for global customers which exceed expectations through dedication, expertise, quality and trust. We strive to be the recognised and trusted partner in delivering unrivaled coating solutions for protecting a wide range of assets in the resource, industrial and commercial sectors.

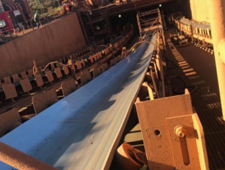

BELTSHIELD®

BeltShield® is the first 100% solids, complete bond system for rubber conveyor belt repair.

MINING SOLUTIONS

ShieldCrete® provides the mining industry with an exclusive and effective range of high-quality coating solutions. Our advanced coating solutions can extend the life expectancy of your mining equipment, reducing repairs and replacement costs.

PROJECT HIGHLIGHT

Pilbara, WA, Australia – The client was one of the biggest iron ore miners in the world. They required a 20km conveyor belt to last until the next planned major shutdown. As the first full-scale trial, our client applied the BeltShield® system to the belt when it was stationary. The belt owner wanted 6 weeks. Turns out it was still going 12 months later! They did further sections of the belt in additional short shuts and are now talking about using the Beltshield system to extend the belt replacement by up to 5 years!

What does this mean?

Sure, it is nice to talk about what can be achieved when you choose ShieldCrete. But how do we achieve these lofty goals of asset protection?

Unlike other product suppliers, we provide solutions that are carefully considered for:

Your surface to be protected

Your exposure constraints.

Your required timeframes.

Your budget.

Everyone’s safety.

For more on our asset protection solutions, click on the relevant application solution category or specific product category below, or Contact Us with your specific requirements.

OUR SOLUTIONS

MINING

WATERPROOFING

RAIL

AUTOMOTIVE

MARINE

CONSTRUCTION

UTILITY

Our focus is on world-leading technologies that push the boundaries of protective coating performance. We work with our own formulations as well as with leading suppliers from around the world to bring you the best solutions available.

Our polyurea’s are the latest formulations that overcome a lot of the drawbacks with older elastomers. ShieldPoly was developed with leading polyurea chemists to have excellent physical properties for extreme environments we service, and of course ease of spraying for the applicator.

Our fire protection coating for cables is a unique intumescent coating that outperforms its ablative competitors for external UV exposure, durability and fire performance. It is much safer to use too, as it contains no halogens or glass fibres.

We have two options for the protection of power poles from bushfires. Our first option is suited for in-field applications to reduce wasted money coating poles that are used in town. Our alternative is a polyurea which is ideal for factory application on new poles. Both have life expectancies of at least 40 years.

Our concrete curing, sealing and protection solutions are second to none, beating all the competition in comparative tests for some of the most iconic projects around the world. When combining the ShieldSeal range of products with our crack injection solutions, we can reduce the amount of crack injection needed to seal concrete by up to 80%!

Our general waterproofing membranes, scratch resistant anti-slip coatings, insulating coatings and epoxies out-perform some of the biggest names in the business and we could go on for ages. But we will leave it up to you to discover more or contact us to ask about specific products for your protection requirements.

FEATURED CASE STUDY

Copper Concentrate Dewatering Plant – Concrete Protection

The engineers were concerned that the copper concentrate would attack the concrete and reduce the service life of the processing facility. Copper sulphate is harmful to the concrete asset and its steel reinforcement due to its galvanic reaction with the steel and the acidity of the solution. Being an elevated slab meant that any loss of strength due to corrosion is particularly critical.

After consulting ShieldCrete®, it was decided to use a high durability bridge mix and use ShieldSeal SCP-743/P3 as the curing compound to seal the concrete against ingress of the solution. The bridge mix began presenting some shrinkage issues at the re-entrant corners and a few other places before we could even get on the slab to apply the curing compound.

OUR CASE STUDIES

We have completed a wide range of projects around the world, here are some of the highlights.